Product Description

– PRODUCT DETAILS –

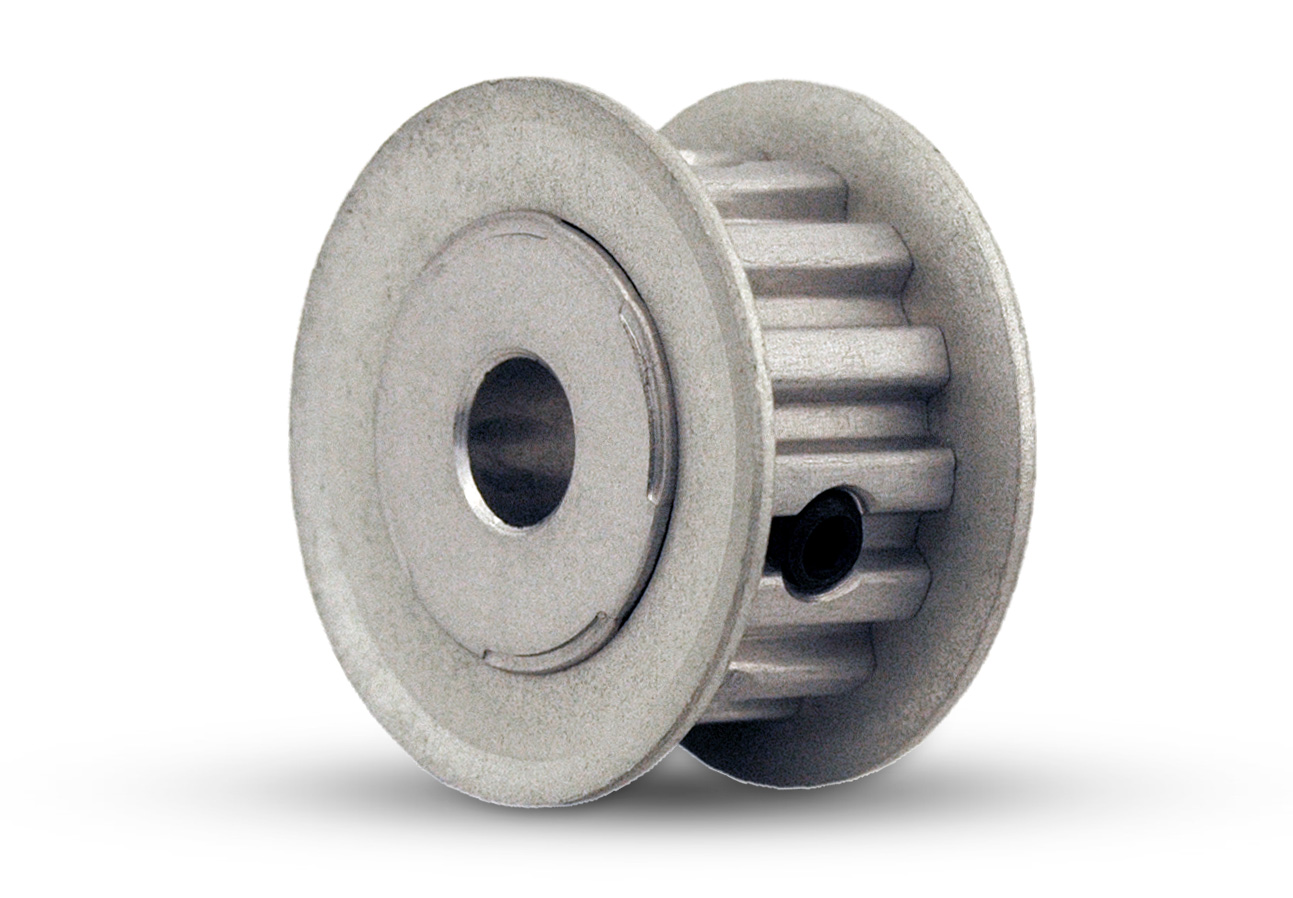

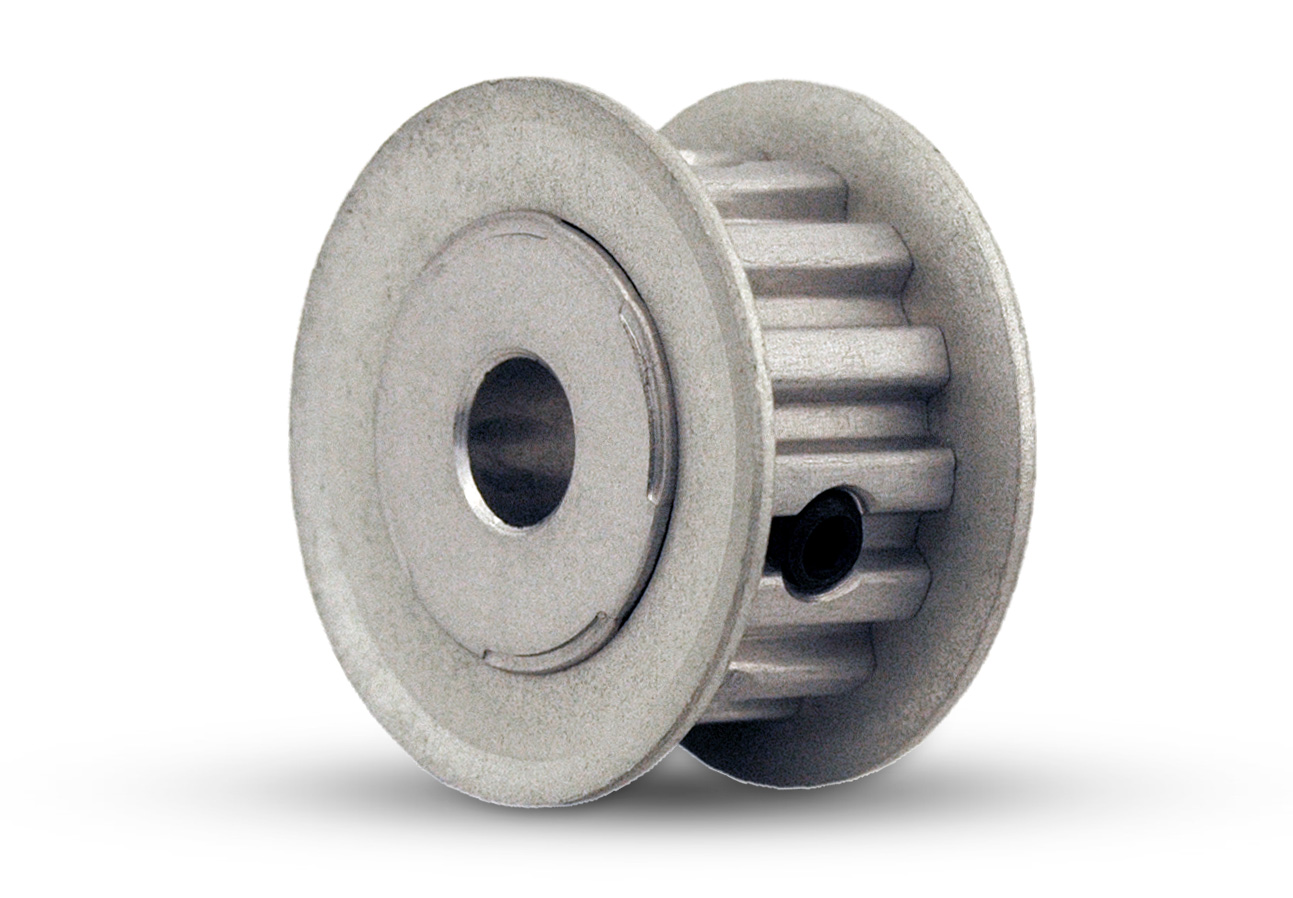

| Product name | Tractor Pulley Lower, XL-Type Aluminum Timing Pulley, 18 Tooth Type-XL (0.375″ BELT) | |

| Material | Aluminum | |

| Production Capacity | 5000PCS /Month | |

| Application | Our products are widely used in mechanical components parts for Industrial | |

| Specification | According to customer’s drawing or sample. | |

| Services | OEM, design, customized | |

| Tolerance | According to Drawing | |

| Surface treatment | – Passivation – Polishing – Anodizing – Sand blasting – Electroplating(color, blue, white, black zinc, Ni, Cr, tin, copper, silver) – Hot-dip galvanizing – Black oxide coating – Electrophoresis – Heat-disposing(Normalizing, Annealing, Quenching, Tempering, etc.) – Spray-Paint – Rust preventive oil |

|

| MOQ | 100 piece | |

| Package | Plastic, Carton, Plywood Case, Pallet | |

| Samples | We can make sample. | |

| Certificate | ISO9001: 2015 quality management system certificate | |

| Payment Terms | Bank Transfer | |

| Delivery time | Subject to negotiation date | |

| Shipping Port | ZheJiang | |

– HONOR & QUALIFICATION –

Since 2000, we have been maintaining certification, standardizing the company’s business activities in accordance with the requirements of quality management system standards, and taking increasing customer satisfaction as our business purpose.

– FACTORY –

– PACKAGE & SHIPPING –

Packaging steps:

Each piece put in on carton box, wood case, Plastics Packaging, pallet, etc.

Mode of shipping:

Shipping by air, sea or car.

By sea for batch goods;

Customs specifying freight forwarders or negotiable shipping methods.

– OUR SERVICES –

1. Could make product for customer according to customer samples or drawings.

2. Can deal with various drawings soft wares: PRO/E, Auto CAD, Slid Work, UG, etc.

3. Could offer samples for free if the sample is simple and low value.

4. Submit samples with official inspection reports including material report,mechanical property report and dimensional report.

5. Can provide the third party inspection report.

6. Could provide at least 1 year quality guarantee after customer receives the products.

7. We could supply storage service for customer if required.

– FAQ –

Q1. How can we quote for you?

Please send us enquiry by email, with all the technical drawings you have. Such as material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less.

Q2. How can I get a sample to check your quality?

After price confirmed, you can requiry for samples to check quality.

If you need the samples, we will charge for the sample cost.

But the sample cost can be refundable when your quantity of first order is above the MOQ.

Q3. Can you do OEM for us?

Yes, the product packing can be designed as you want.

Please feel free to contact us if you have any question.

| Certification: | ISO |

|---|---|

| Pulley Sizes: | 18 Tooth Type-XL ( 0.375′′ Belt ) |

| Manufacturing Process: | Forging |

| Material: | Aluminum |

| Surface Treatment: | Clear Anodize |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do XL pulleys contribute to energy conservation and reduced friction in systems?

XL pulleys play a significant role in energy conservation and reducing friction in systems. Here is a detailed explanation of how XL pulleys contribute to these benefits:

1. Efficient Power Transmission:

XL pulleys are designed to transmit power from the driving source, such as an electric motor or engine, to the driven component, such as a conveyor belt or machine. By utilizing toothed belts, also known as timing belts, XL pulleys provide a positive engagement between the belt and pulley, ensuring efficient power transfer without slippage. This efficient power transmission minimizes energy loss, conserving energy in the system.

2. Reduced Friction:

XL pulleys, when used with compatible timing belts, offer low friction power transmission. The teeth on the pulleys mesh with the teeth on the timing belt, creating a positive engagement that reduces slippage and associated friction. The reduced friction between the pulleys and the belt results in improved efficiency, as less energy is wasted as heat and the overall system friction is minimized.

3. Proper Belt Tension:

XL pulleys contribute to energy conservation by facilitating proper belt tensioning. The accurate design and dimensions of the pulleys, combined with tensioning mechanisms, allow for optimal belt tension adjustment. Proper belt tension ensures the right balance between grip and flexibility, minimizing belt slip and energy loss due to excessive tension or slack.

4. Lightweight Design:

XL pulleys are often designed to be lightweight without compromising strength and durability. The use of lightweight materials, such as aluminum alloys or engineered polymers, reduces the rotational inertia of the pulleys. Lower rotational inertia requires less energy to accelerate or decelerate the pulleys, contributing to energy conservation and improved system responsiveness.

5. Smooth Operation:

XL pulleys, when manufactured with precision and high surface quality, enable smooth operation in power transmission systems. The even distribution of forces and reduced friction between the pulleys and timing belt result in reduced vibration, noise, and wear. Smooth operation minimizes energy loss due to mechanical inefficiencies and ensures the system operates at optimal performance levels.

6. System Optimization:

XL pulleys can be selected and designed to optimize system performance in terms of energy conservation and reduced friction. Factors such as the pulley size, tooth profile, and material selection can be tailored to match the specific system requirements. By optimizing the pulley design and characteristics, energy losses and friction can be minimized, leading to improved overall system efficiency.

In summary, XL pulleys contribute to energy conservation and reduced friction in systems through efficient power transmission, reduced friction between pulleys and belts, proper belt tensioning, lightweight design, smooth operation, and system optimization. By utilizing these features, XL pulleys help minimize energy wastage, improve system efficiency, and reduce friction-related wear and tear, ultimately leading to energy savings and increased operational lifespan of the system.

Can XL pulleys be used in both industrial and automotive applications?

Yes, XL pulleys can be used in both industrial and automotive applications. Here’s a detailed explanation:

1. Industrial Applications:

XL pulleys find extensive use in various industrial applications due to their reliable power transmission capabilities. They are commonly employed in industries such as manufacturing, automation, packaging, material handling, and robotics. Industrial machinery and equipment, such as conveyor systems, CNC machines, printing presses, and assembly lines, often utilize XL pulleys to transfer rotational motion and achieve precise motion control.

XL pulleys offer advantages such as accurate positioning, high efficiency, low noise, and compactness, making them suitable for a wide range of industrial applications. The ability to handle different speed ratios and provide maintenance-free operation further enhances their versatility in industrial settings.

2. Automotive Applications:

XL pulleys also find application in the automotive industry, albeit in more specific areas. In automotive systems, XL pulleys are commonly used in timing belt drives. These drives are responsible for synchronizing the rotation of the engine’s camshaft(s) with the crankshaft, ensuring precise valve timing and efficient engine operation.

Timing belt systems in automotive engines require reliable and accurate power transmission, and XL pulleys, along with the corresponding timing belts, provide the necessary performance. They offer advantages such as precise motion control, low noise, and compactness, which are essential for efficient engine operation. XL pulleys used in automotive applications are designed to meet the specific requirements of the engine, considering factors such as load capacity, speed ratios, and durability.

It’s worth noting that while XL pulleys are suitable for many industrial and automotive applications, it’s essential to consider the specific requirements and operating conditions of each application. Factors such as load capacity, speed, environmental conditions, and maintenance considerations should be taken into account when selecting and implementing XL pulleys in industrial or automotive systems.

In which applications and industries are XL pulleys commonly used?

XL pulleys find extensive use in various applications and industries that require precise motion control and power transmission. Here are some common applications and industries where XL pulleys are commonly employed:

1. Robotics:

XL pulleys are utilized in robotic systems for precise positioning and movement control of robot arms, grippers, and other robotic components. They enable accurate and synchronized motion, allowing robots to perform complex tasks with precision.

2. CNC Machines:

CNC (Computer Numerical Control) machines, such as milling machines and lathes, rely on XL pulleys for precise control of spindle speed and tool positioning. The accurate motion provided by XL pulleys ensures high-quality machining and dimensional accuracy in CNC operations.

3. 3D Printers:

XL pulleys are commonly used in 3D printers to control the movement of the print head and the positioning of the build platform. The precise motion control facilitated by XL pulleys contributes to the accuracy and fine detail of the printed objects.

4. Automated Systems:

XL pulleys are employed in various automated systems, including conveyor systems, packaging machinery, assembly lines, and material handling equipment. These systems require synchronized and precise motion to ensure efficient and accurate operation.

5. Industrial Machinery:

In industrial settings, XL pulleys are used in a wide range of machinery, such as textile machines, printing presses, woodworking equipment, and industrial automation systems. They provide reliable power transmission and motion control in these demanding applications.

6. Automotive Industry:

XL pulleys are utilized in automotive applications, including engine timing systems, accessory drives, and power steering systems. The precise control and synchronization offered by XL pulleys contribute to efficient and reliable operation of these automotive components.

7. Medical Devices:

In the medical field, XL pulleys are found in equipment such as diagnostic machines, laboratory automation systems, and surgical instruments. They enable accurate movement and positioning, ensuring the precision required for medical procedures and diagnostics.

8. Aerospace and Defense:

XL pulleys are used in aerospace and defense applications, such as satellite positioning systems, guidance systems, and unmanned aerial vehicles (UAVs). The reliable motion control provided by XL pulleys is crucial for the accurate operation of these aerospace and defense systems.

9. Research and Development:

In research and development laboratories, XL pulleys are employed in experimental setups, prototyping systems, and testing equipment. Their precise motion control capabilities support the development and validation of new technologies and products.

In summary, XL pulleys are commonly used in applications and industries that require precise motion control and power transmission. Their versatility and reliability make them suitable for a wide range of applications, from robotics and CNC machines to 3D printers, automated systems, automotive components, medical devices, aerospace, and research and development.

editor by CX

2023-10-09